A notable difference between eurosens Dominator fuel level sensors and similar products from other manufacturers is the way the sensor is attached to the tank via an intermediate bayonet plate.

Conventional fuel level sensors are fixed directly to the fuel tank with self-tapping screws through the rubber gasket.

|

|

Mounting a conventional fuel level sensor

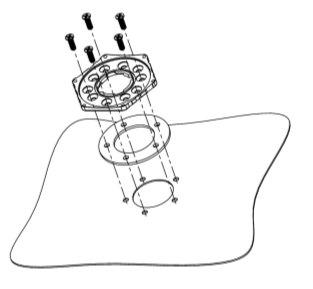

To mount the Dominator, a solid bayonet plate is attached to the tank with self-tapping screws through the gasket. The sensor itself is clamped into the bayonet plate and then sealed against removal.

|

|

Mounting the eurosens Dominator

What advantages this method of attachment gives us.

This mounting method is reusable and allows convenient maintenance of the installed sensor. The following issues may arise during the operation of fuel level sensors:

- The gauge begins to show a full tank – most likely water has accumulated on the bottom of the tank, which leads to incorrect readings. To check this version the sensor should be removed from the fuel tank and dipped into clean fuel.

- The space between the electrodes of the sensor is clogged by conductive dirt. The sensor must be removed from the tank for diagnosis and cleaning.

- The sensor was damaged failed or malfunctioned – the sensor must be replaced.

We are not saying that such problems occurs with every sensor installed, but they are familiar to anyone who is involved in fuel consumption monitoring on a regular basis.

In this case, any removal of the sensor of traditional design with a flange leads to a difficult choice – either to fix the sensor with self-tapping screws in the old holes with loss of tightness and rigidity of attachment or to drill new holes.

The results from repeatedly removing the fuel level sensors can be seen in the photo below.

|

|

With each disassembly the tightness of the sensor installation deteriorates due to the increasing number of holes in the fuel tank.

When dismounting the eurosens Dominator, it is not necessary to remove the self-tapping screws securing the bayonet plate. It is sufficient to remove the seal and release the sensor from the bayonet. After service work, the sensor is clamped into the bayonet and sealed.

Whether or not you need to think about how to maintain them in the future when installing fuel level sensors is up to you 🙂

P.S.

Leading vehicle manufacturers have been using fuel level sensors with bayonet mounts for years (SCANIA, Volvo, Man , IVECO, etc.).

We are in social media

Facebook

LinkedIn

Youtube